SHRINK SLEEVE

SEAMING (SR)

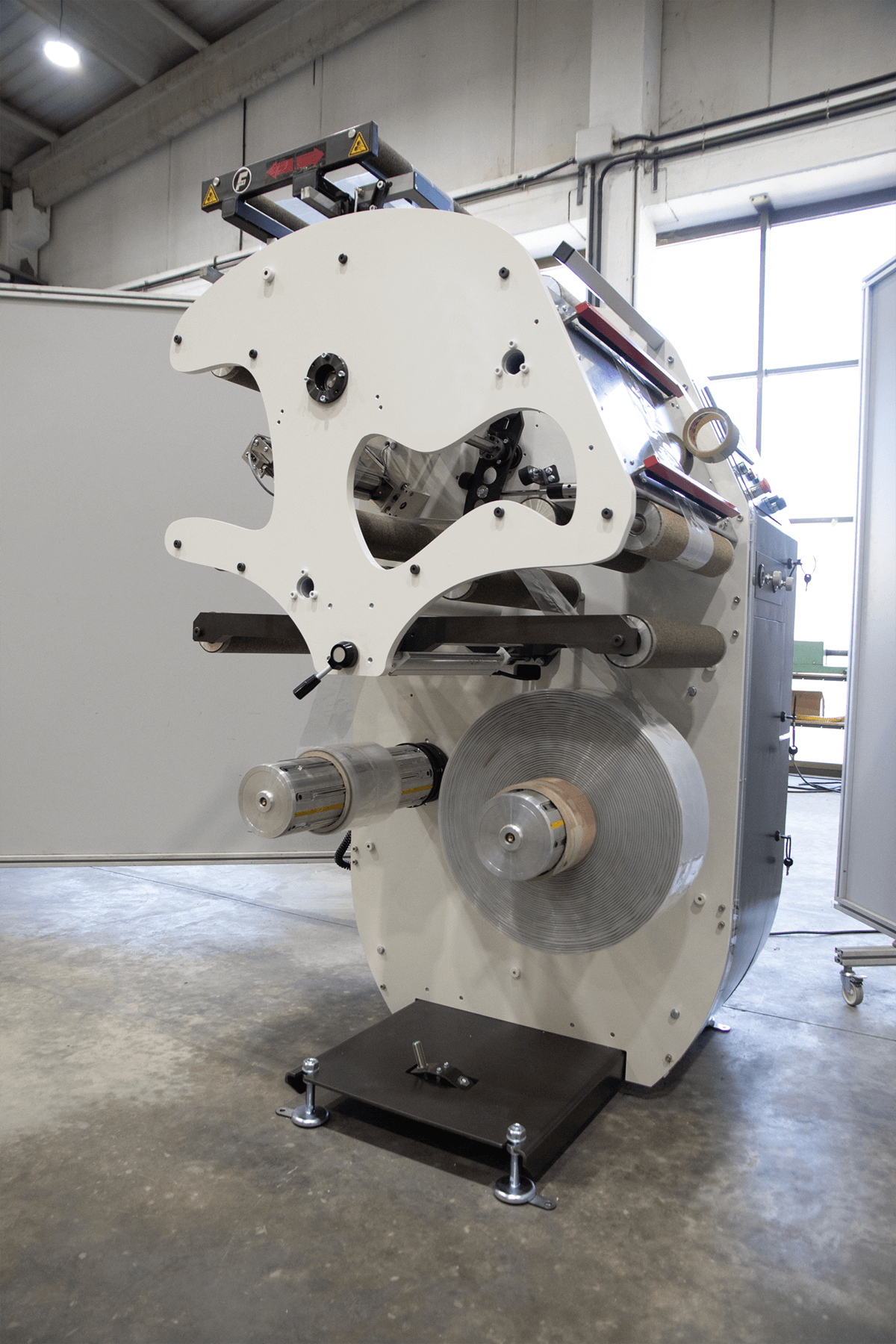

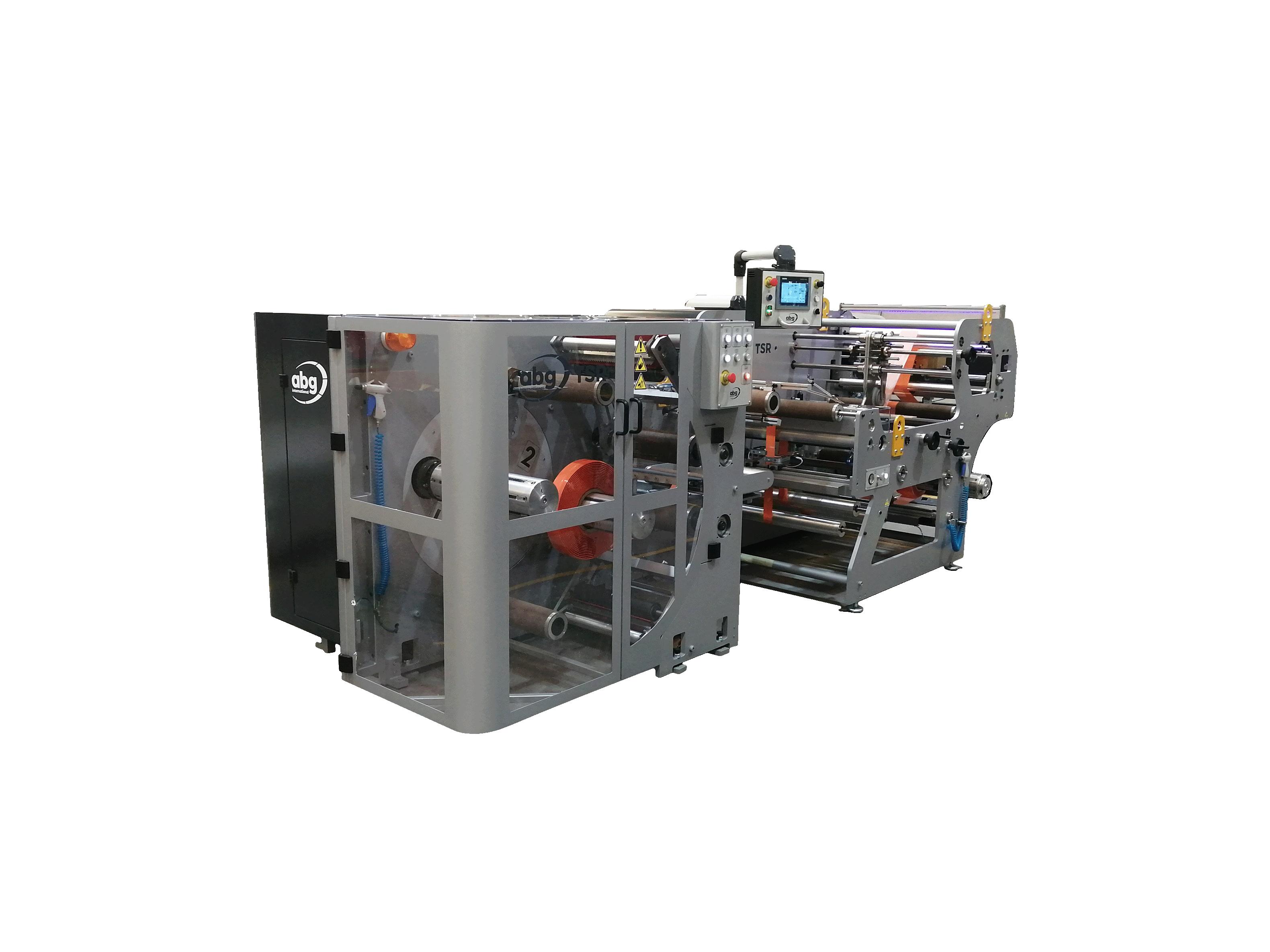

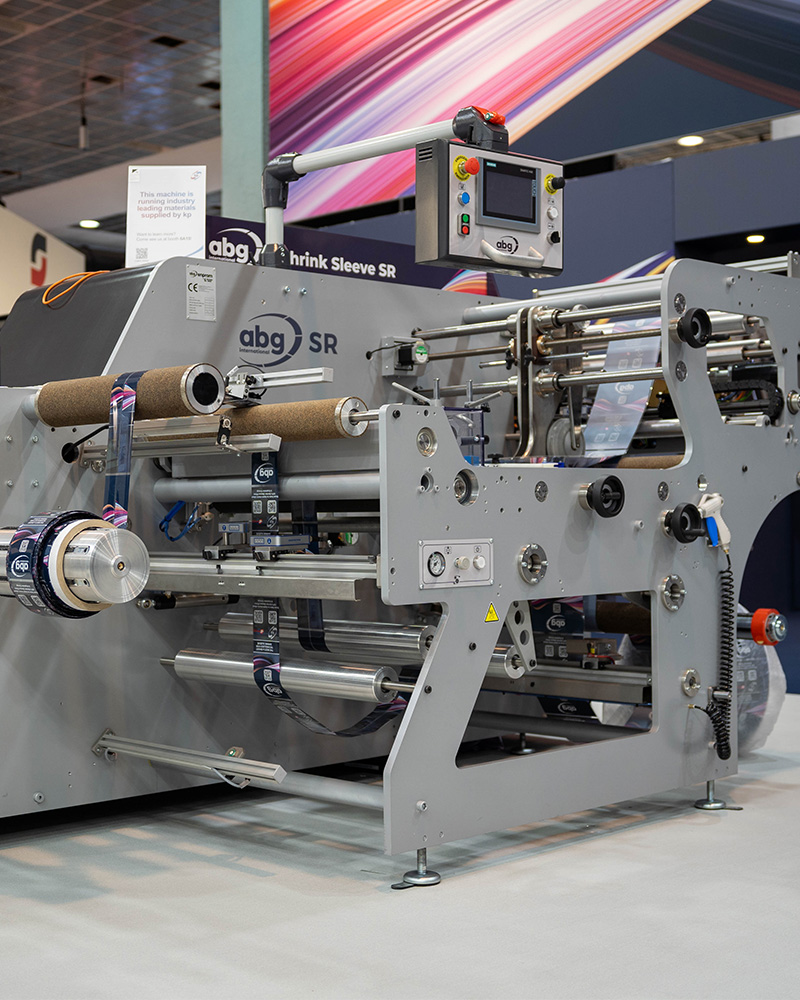

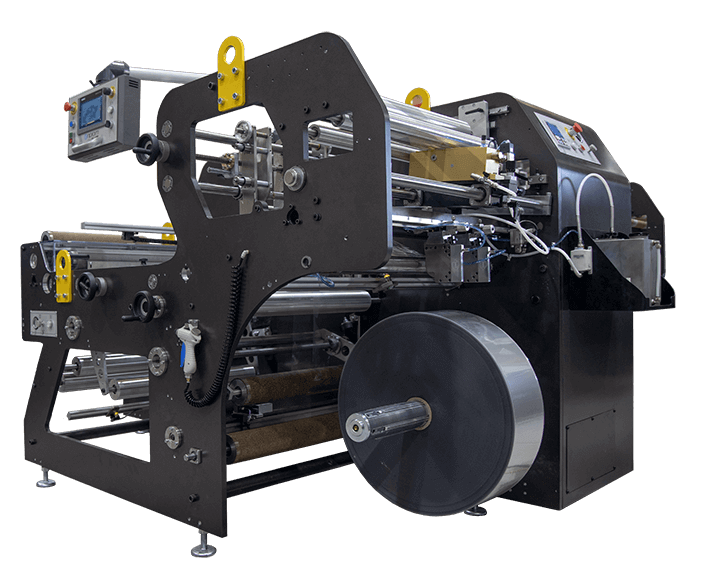

The Shrink Sleeve Seaming Machine (SR), converts a flat film reel into a single sleeve label or multiple sleeves. This label, once placed to the final product, conforms to the shape of the container.

The SR ensures a constant and strong weld, so that it doesn’t break when heat is applied, as well as a flat, clean weld due to our unique application system. The chemical weld is applied with solvent, using our proprietary solvent grafix.

The SR is unique, as it uses Smart Wheel which is a bespoke solution from ABG. The Smart Wheel applies a consistent layer of solvent creating numerous benefits for our customers including: less waste, greater consistency of solvent application and a more reliable weld.

We offer a range of flexible

packaging options

The SR provides reliable product quality and saves time with its motorised roller system.

- Unique Smart Wheel System – our unique solvent application system with the motorised roller system

- Reliable – increased reliability of seaming, allowing you to avoid any blockages as the system distributes the application uniformly

- Product Quality – improve the final product quality as the solvent is applied to the edge, allowing you to adjust the width easily

- Time Saving – the online inspection kit enables the application system to avoid subsequent inspection processes, almost entirely

- Laser Perforation – this can also be retrofitted to existing seaming machines, providing quicker turnaround times and increased efficiency. In addition no tooling is required by using the laser to make perforations

![]() View and download our Shrink Sleeve

View and download our Shrink Sleeve

brochure by clicking here.

Related

Products

A fresh look at

digital finishing

Innovative digital

finishing machines

Easy to use, quick to set up, fast, automated, flexible

and reliable – just some of the reasons clients across the globe choose ABG machines.