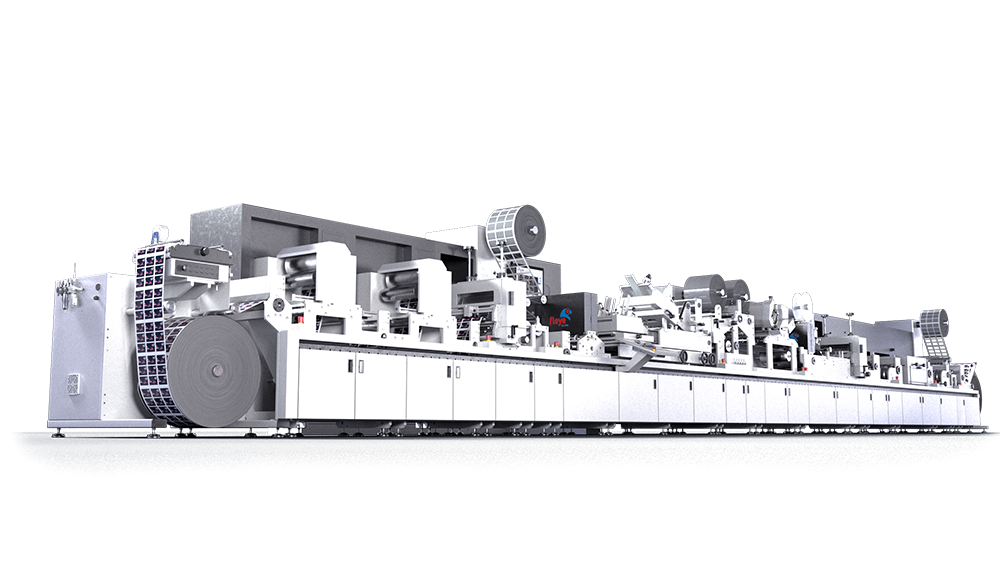

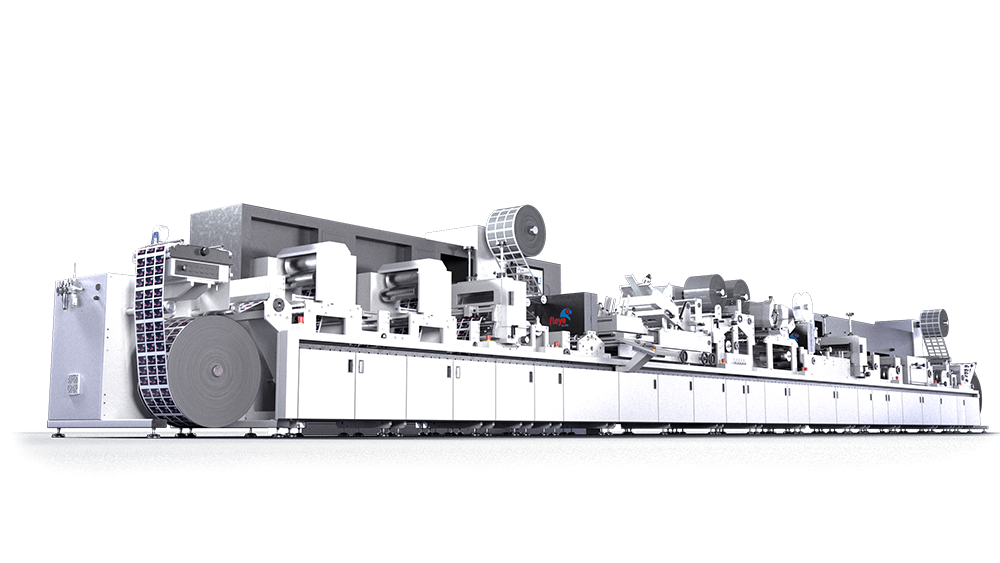

Omega

B5010

The Omega B5010 is a modular booklet system which can process up to 36,000 booklet labels per hour. Equipped with ABG’s own unique designed booklet label feeding system, it can handle booklets ranging in length from 30mm to 280mm, and in width from 80mm to 320mm.

Booklets can contain up to 56 sheets/112 pages – and be secured by hot or cold glue as well as by lamination, depending on your need.

A modular masterclass

in versatility

Omega B5010 features include:

- Effortlessly switch between booklet lengths and widths

- Multiple adhesion methods – hot and cold glue or lamination

- Camera inspection ensures accuracy of placement

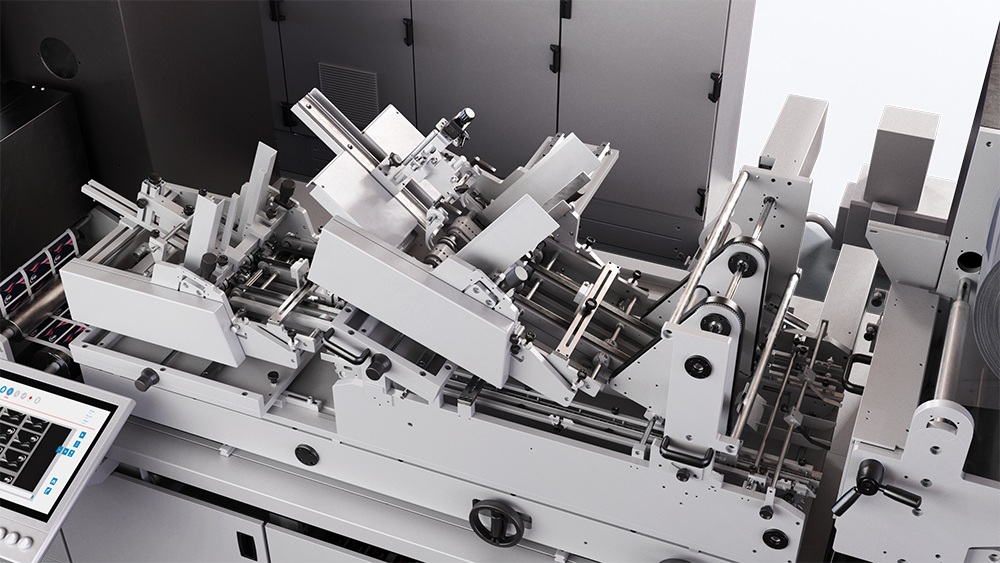

About

Omega B5010

- Integrated flexo unit with register control and UV-drying system.

- Booklets on the Omega B5010 are fed by a vacuum belt. A conveying system will transport the booklet and attach it to the base web.

- Camera inspection with marking system for the print inspection booklets top page and for the correct placement on the base web.

- Using a rotary knife or (alternatively) a razor slitting unit, the die cut booklet labels can be cut into single rolls before rewinding.

![]() View and download the Omega B5010

View and download the Omega B5010

brochure by clicking here.

Related

Products

A fresh look at

digital finishing

digital finishing

Innovative digital

finishing machines

finishing machines

Easy to use, quick to set up, fast, automated, flexible

and reliable – just some of the reasons clients across the globe choose ABG machines.

and reliable – just some of the reasons clients across the globe choose ABG machines.