ENGINEERING

TOMORROW'S

SOLUTIONS TODAY

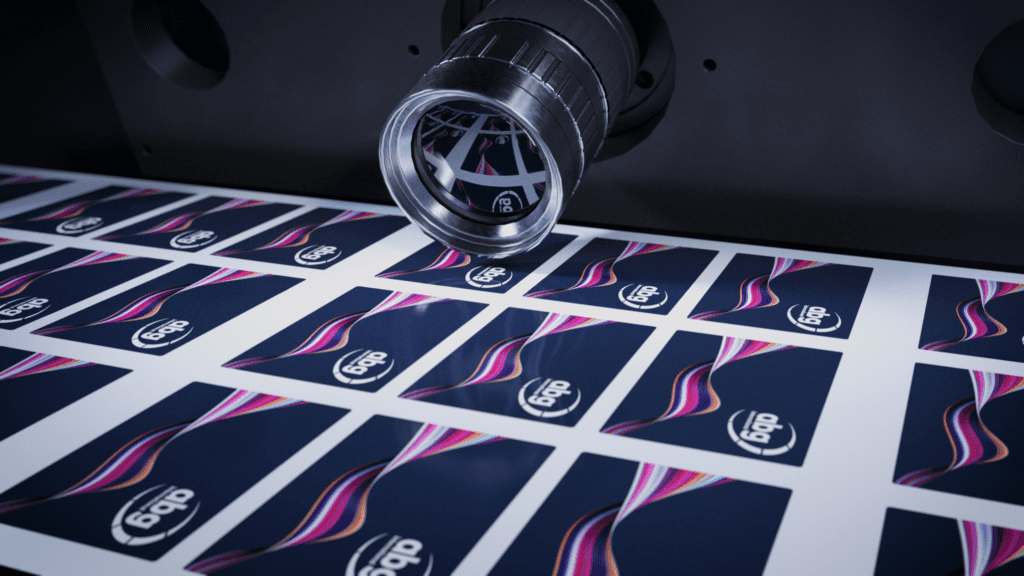

All eyes on innovative

digital finishing

Innovative print

finishing equipment

Shorter lead times, reduced inventory, less waste and improved cash flow – just some of the reasons clients across the globe choose A B Graphic International machines.

Perfected by combining

years of feedback

Inspection Slitter Rewinding

A powerful efficient and versatile label finishing system, which offers three high speed functions: slitting, rewinding and inspection.

The most accurate

laser converting

Accurate results with an automated set up

An innovative digital finishing machine with start-of-the-art-laser cutting technology.

Customer driven

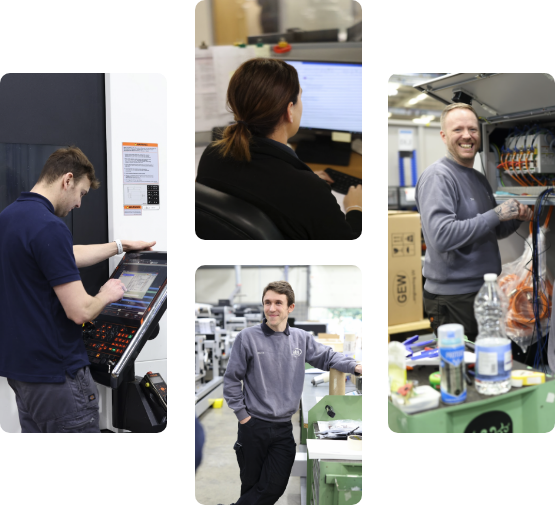

innovation

Delivering

unparalleled service

Our market leading engineers deliver unparalleled service and

use client feedback to perfect our labelling solutions.

Get in touch

with ABG today