Digicon

SERIES 3

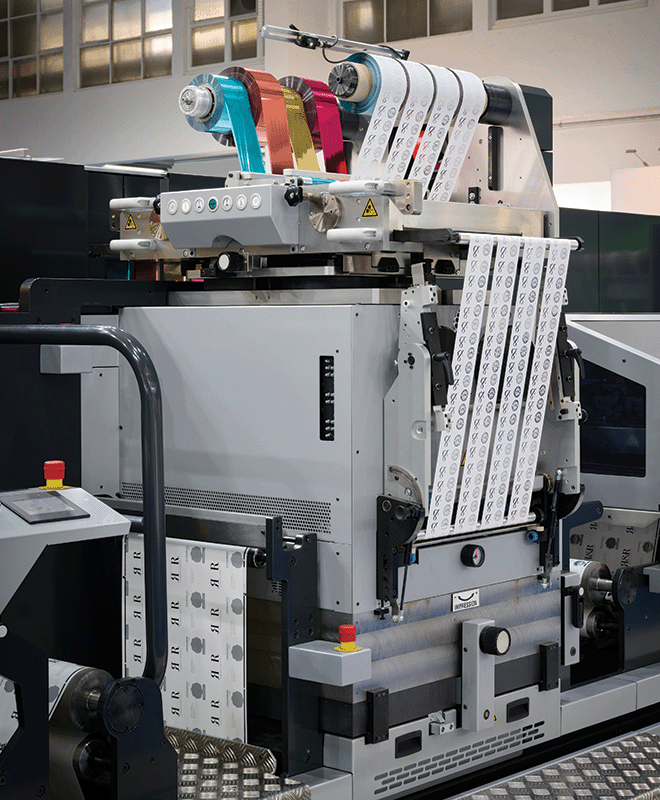

The Digicon Series 3 is our flagship machine with thousands of installations worldwide. Modular in design, so that they can be designed to meet your business needs, enables you to create a clear and competitive advantage.

Leading digital

print finishing

Designed for any digital printing application, the Digicon Series 3 can be used roll-to-roll or roll-to-sheet.

- Accurate – built with precision to ensure consistent results.

- Flexible – with modules and options to give you a competitive edge.

- Easy-to-use – with intuitive controls and low-cost maintenance.

- Time saving – with a wide range of automated functions.

- Fast – and efficient, keeping pace with your press.

- Wider Web Applications – available in 430mm, helping customers convert wider digital webs with the highest quality finishing from ABG.

About

Digicon Series 3

- Die plate loading and un-loading

- Fast Track Die Cutting – the world’s fastest semi-rotary die cutting system – able to run at 180 metres per minute and work in-line with the world’s fastest digital print engines

- Gap sensing and knife setting – to save time on set up and changeovers

- Big Foot 50-ton capacity hot foil and embossing module – with multiple foil feeding across and along the web – to create new effects and finishes that will give you a competitive advantage

- Flatbed screen printing module – to add value with relief varnishes or vibrant screen inks

- Crossover module – to create multi-layered, novelty or promotional labels, digitally

- Lamination in register module – enables pre-printed web to be laminated to the main web in perfect register

- DigiJet – digital embellishment module to create high quality digital embellishments

![]() View and download the Digicon Series 3

View and download the Digicon Series 3

brochure by clicking here.

![]() View and download the Digicon Series 3

View and download the Digicon Series 3

Technical Specifications here.

Related

Products

A fresh look at

digital finishing

Innovative digital

finishing machines

Easy to use, quick to set up, fast, automated, flexible

and reliable – just some of the reasons clients across the globe choose ABG machines.