DigiLase

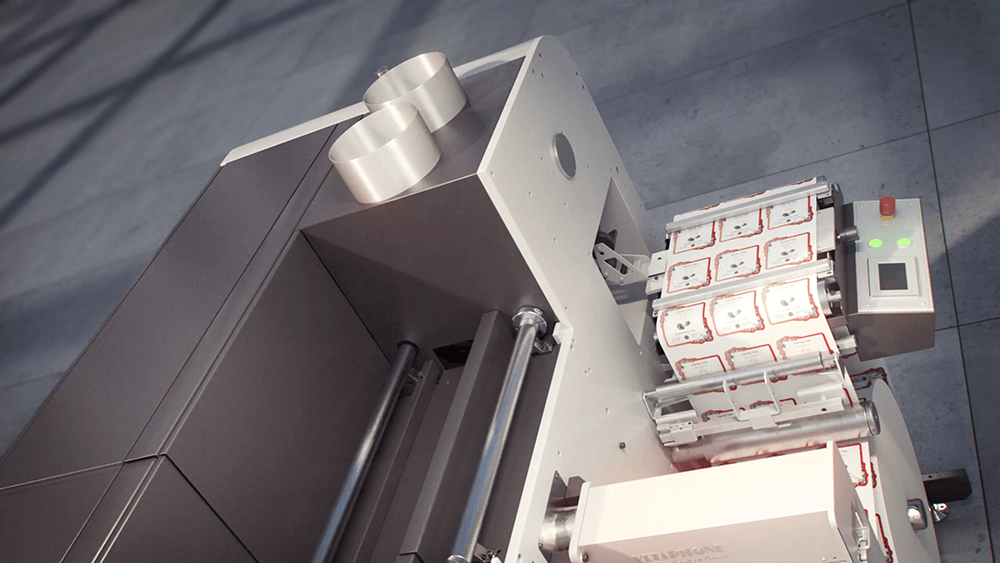

Designed for short print runs, the DigiLase works across a range of applications – from roll to roll, sheet or individual piece.

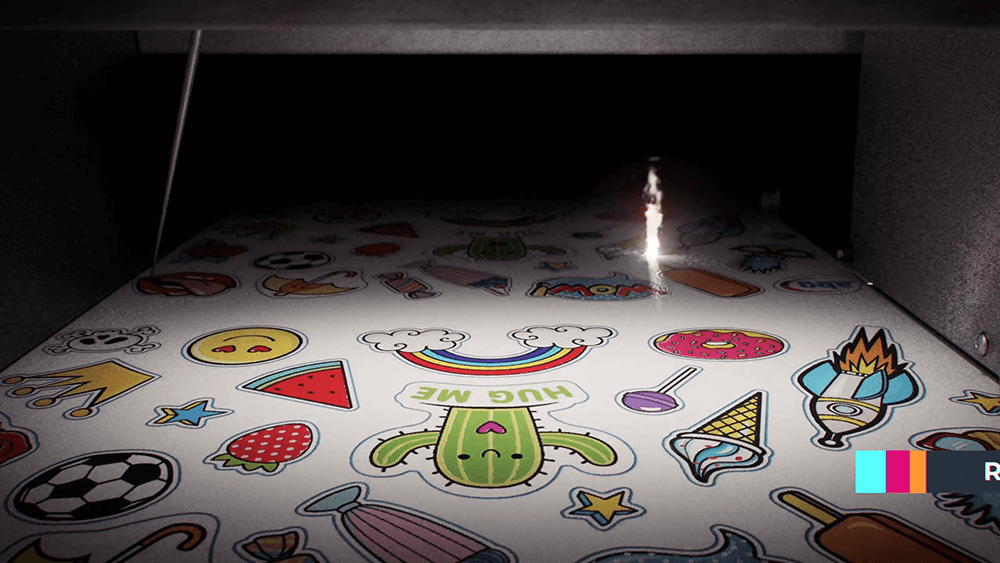

The laser can cut intricate shapes and the fast, fully automated job changeover helps you change jobs with minimal operator input.

Accurate results

with a fully automated set up

The DigiLase makes jobs simple to run – our automatic compiler uses the material type and shape to calibrate:

- The most accurate laser path

- The correct laser power

- The right job speed

About

DigiLase

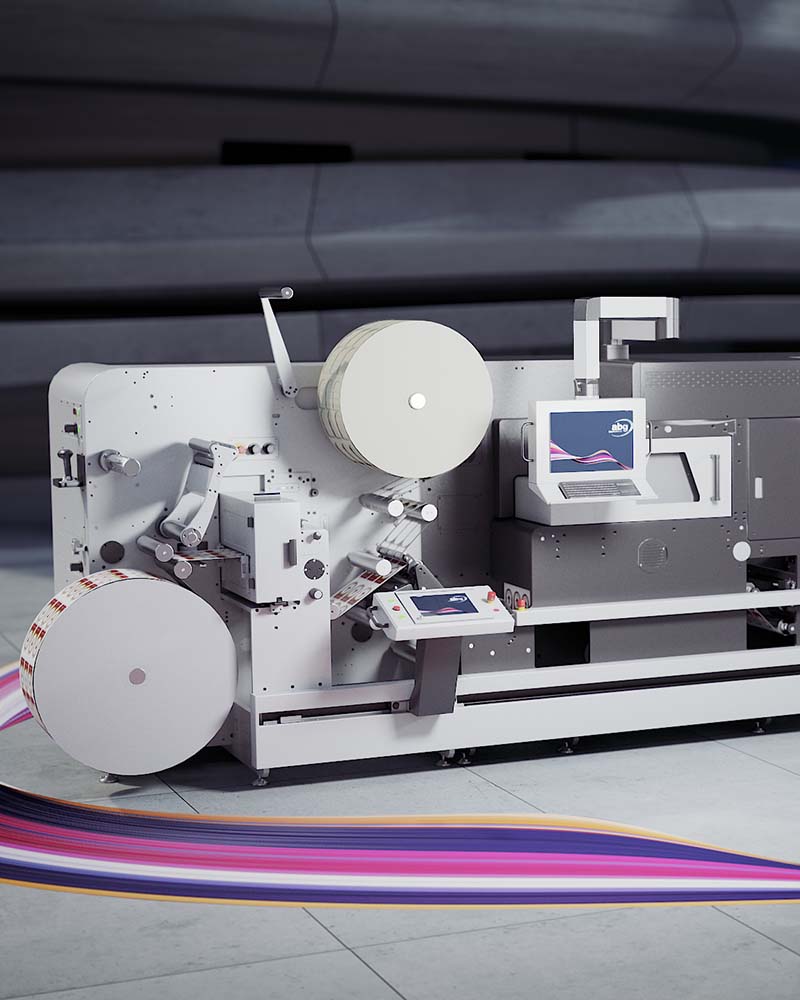

- Time saving – Fast, fully automated job changeover and simple pre-press set-up

- Reliable results – Cutting speed and power are automatically managed by the software developed by ABG

- Accurate finishing – Digitally controlled fine laser beam for cutting intricate shapes on many materials

- Intelligent – Integrates with any Management Information System (MIS)

- Simple to configure – Modules and options to configure the machine exactly as you need

- Flexible – Works across a range of print applications; roll to roll, sheet or individual piece

- Quick set up – No make readies required and saved jobs can be set up for automatic repeats

- Easy to use – Intuitive interface with integrated inspection area and no need for hard tooling

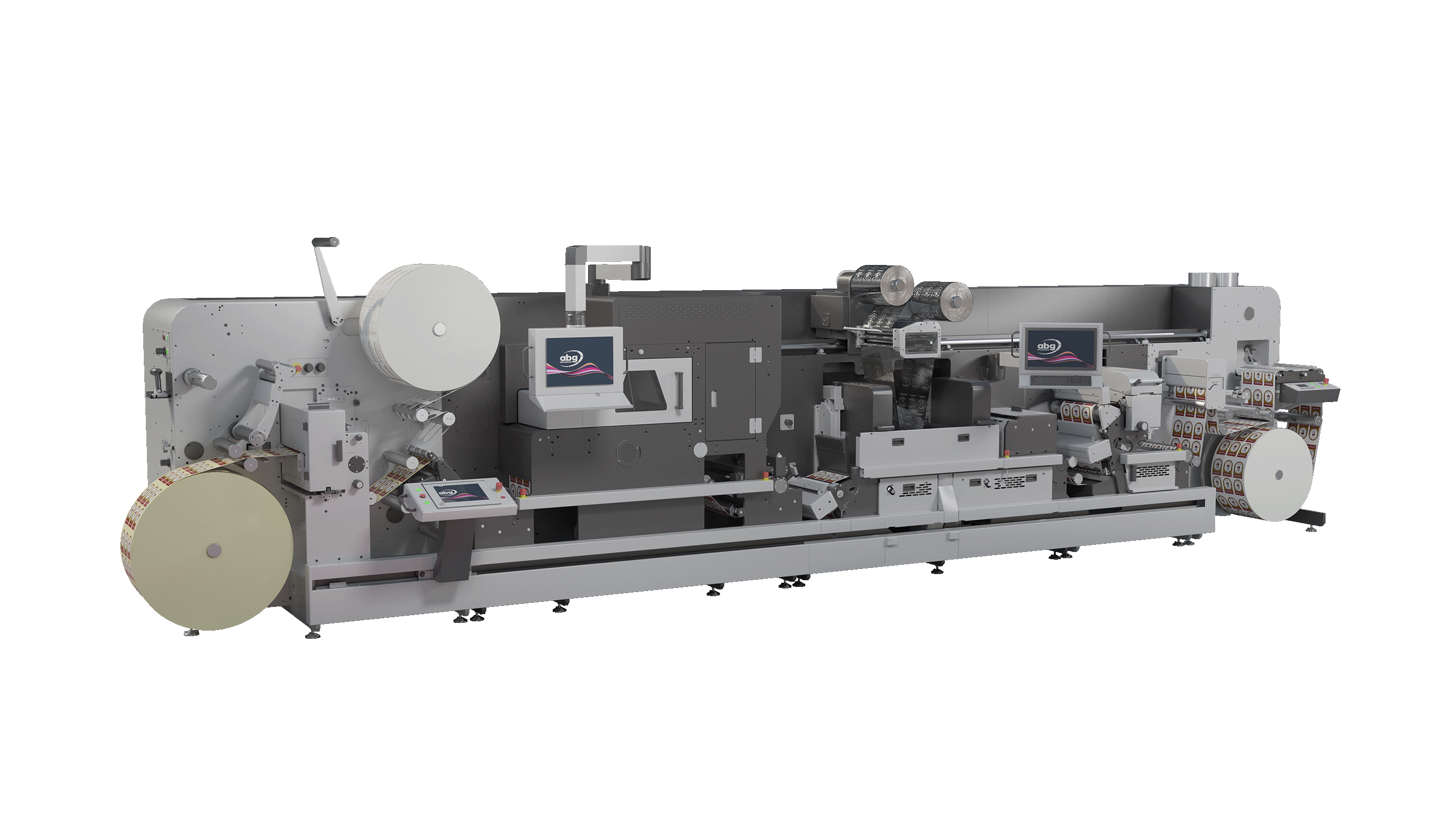

- Seamless integration – The fully versatile machine can be integrated into other digital finishing lines or rotary web-fed machines

![]() View and download the DigiLase

View and download the DigiLase

brochure by clicking here.

Related

Products

A fresh look at

digital finishing

Innovative digital

finishing machines

Easy to use, quick to set up, fast, automated, flexible

and reliable – just some of the reasons clients across the globe choose ABG machines.